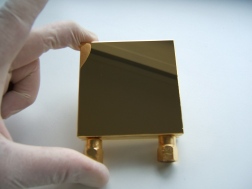

Most of our mirrors are sold for use in typical industrial or laboratory environments. Some applications though need reflective surfaces to work at extreme temperatures or in corrosive environments. We have had good results in polishing Inconel 625 to a laser quality mirror finish. Inconel alloys are oxidation and corrosion resistant materials, well suited for use in extreme environments subjected to pressure and heat. They are widely used in motorsport exhaust systems, rocket motors, and the latest electric vehicles such as the Tesla, in ludicrous mode !

When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains it’s strength over a wide temperature range, attractive for high temperature applications where aluminium and steel would succumb to creep.

Conventional machining is difficult, especially thread cutting. Often profiling and cutting is done by water jet or EDM.

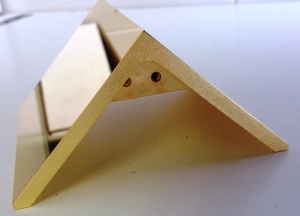

If an acousto-optic modulator (AOM) is being used, a reflective aperture can be used to manipulate one of the beam orders to be reflected and the other to be transmitted. We can make through holes as small as 1 mm diameter very accurately.

If an acousto-optic modulator (AOM) is being used, a reflective aperture can be used to manipulate one of the beam orders to be reflected and the other to be transmitted. We can make through holes as small as 1 mm diameter very accurately.